Product Description

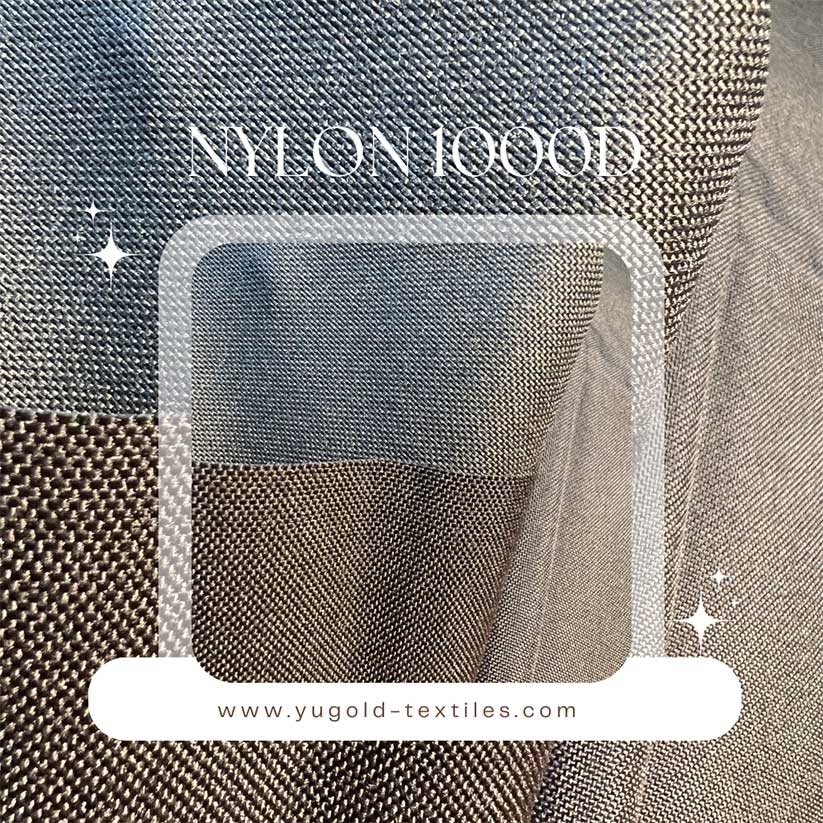

Engineered for demanding use, this 1000D high‑tenacity nylon fabric delivers the tensile and tear strength you expect from a heavy‑duty bag fabric, at a more accessible cost than branded CORDURA® materials. Made in Taiwan with stable quality control, it is ideal for OEM/ODM projects that require consistent performance and fast lead times.

Key Features & Benefits

-

High tensile & tear strength: 1000D denier construction and a tight weave provide strong load-bearing performance and help prevent tearing, even under repeated stress.

-

Excellent abrasion resistance: Textured nylon yarn gives the surface extra resistance to scuffs and wear from daily use and contact with rough surfaces.

-

Coating options (2×PU / lamination): Optional double PU coating or laminated backing enhances water resistance, dimensional stability and fabric body while remaining easy to cut and sew.

-

Production-friendly handling: Suitable for industrial sewing, bar‑tacking and binding; the fabric holds its shape well in structured bags, cases and protective covers.

-

Cost-effective & readily available: Non‑DuPont 1000D nylon offers performance that meets most bag, outdoor and industrial applications, with lower material cost and easier sourcing than branded CORDURA® fabrics.

Typical Applications

- Backpacks and daypacks

- Suitcases, luggage and travel bags

- Tool bags and utility bags

- Outdoor and sports accessories (pouches, gear organizers, waist packs, etc.)

- Protective and industrial covers, cases and equipment sleeves

Why Choose Non‑DuPont 1000D Nylon?

-

Better cost–performance ratio: Maintain high abrasion and tear resistance while reducing material cost, improving product margins.

-

Performance that fits the market: While it differs from original CORDURA® on certain lab metrics, it delivers more than enough durability for most mass‑market bags, outdoor gear and many industrial covers.

-

Stable, flexible supply: Strong availability and broad color options shorten lead times and reduce the risk of out‑of‑stock situations.

-

Growing market acceptance: Increasingly popular in price‑sensitive segments such as everyday backpacks, multi‑purpose bags and promotional items.